Impact Labs is the largest additive manufacturing facility in Israel, operating at production scale across commercial, artistic, and defense-related work. I interned there as part of Torah Tech, a program combining full-time tech internships with Torah study. Impact Labs was where I did my hands-on engineering work.

During my time there, I worked alongside one other intern on the production floor, supporting high-throughput additive manufacturing operations and a wide range of custom projects.

Most day-to-day work centered around the HP 3D Jet Fusion 4200, with two build units rotating continuously between printing, cooldown, and cleanup. Each build unit produced hundreds of parts at a time, so I probably handled tens of thousands of parts over the course of my internship.

My responsibilities focused on post-processing and machine upkeep. I also operated SLS and large-format FDM printers (BigRep One). Coming straight out of high school, this role was an awesome introduction to industrial-scale additive manufacturing, production discipline, and quality control.

Me at the HP cleaning station

PROJECTS

PROSTHETIC LEG BUTTONS

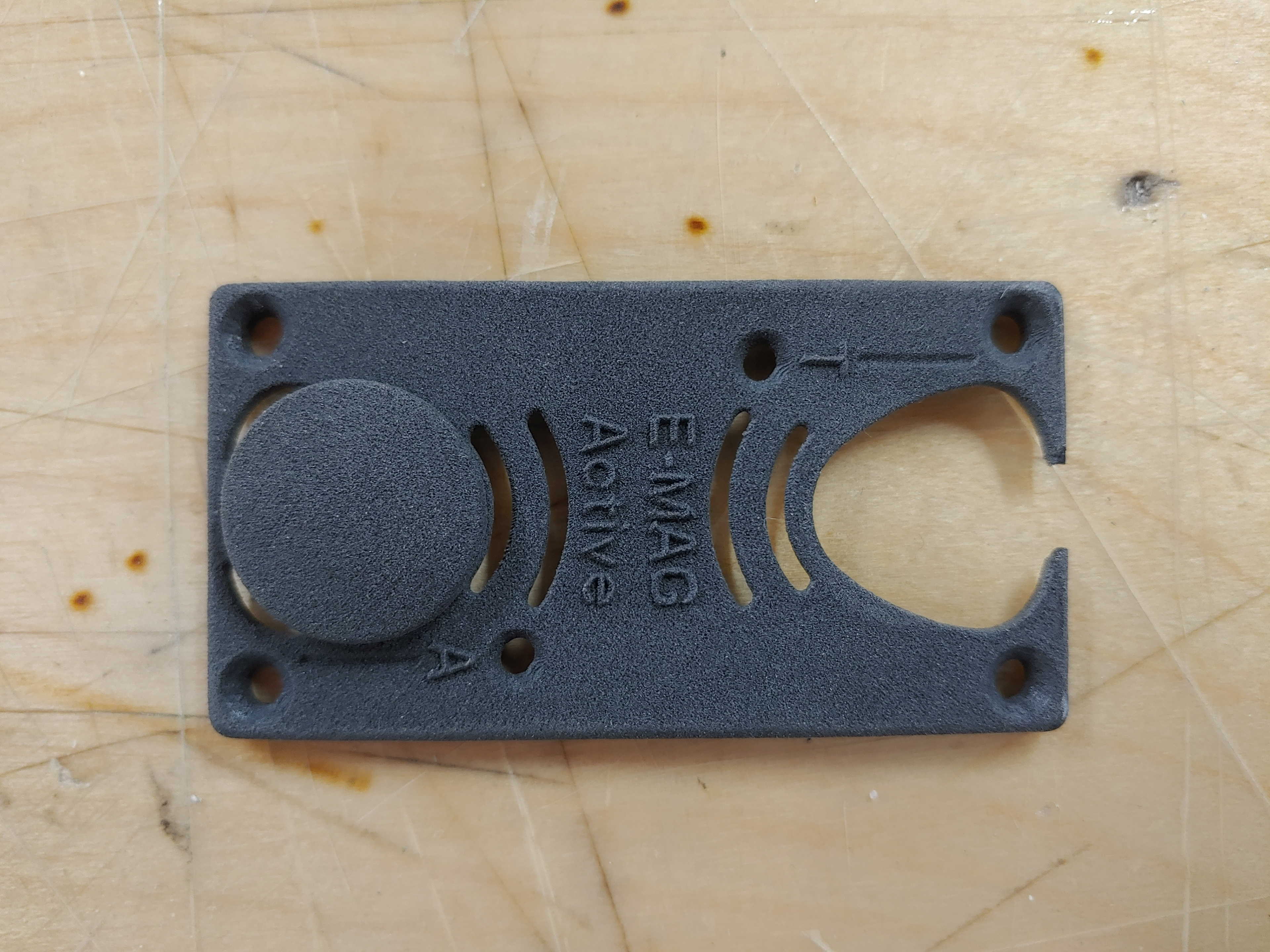

A client came in with a broken button on his prosthetic leg. Replacement parts from the manufacturer were extremely expensive, and the original design had a flaw: the button was easy to accidentally press when brushing against objects.

Working directly with the client, I designed a replacement button with integrated side guard rails to prevent accidental activation. We produced four to five iterations, allowing him to test comfort and usability before settling on a final design.

The result was a significantly cheaper replacement that was also better than the original design. The client was very happy with the outcome.

The original button. One snapped off and there is no guard.

The different design iterations for the new button.

The button installed on the prosthetic.

HOTEND BRACE FOR LARGE-FORMAT FDM PRINTER

Impact Labs owned a 3D Platform 200 Series Workbench Classic with a 1 m × 1 m × 0.5 m build volume, worth roughly $30,000. The printer was rarely used due to the risk of the hotend colliding with printed parts, which could have caused severe damage.

I was tasked with solving this problem. I designed a custom hotend brace that stabilized the assembly and eliminated collision risk. As an upgrade, I also integrated dual fan ducts to address existing cooling issues.

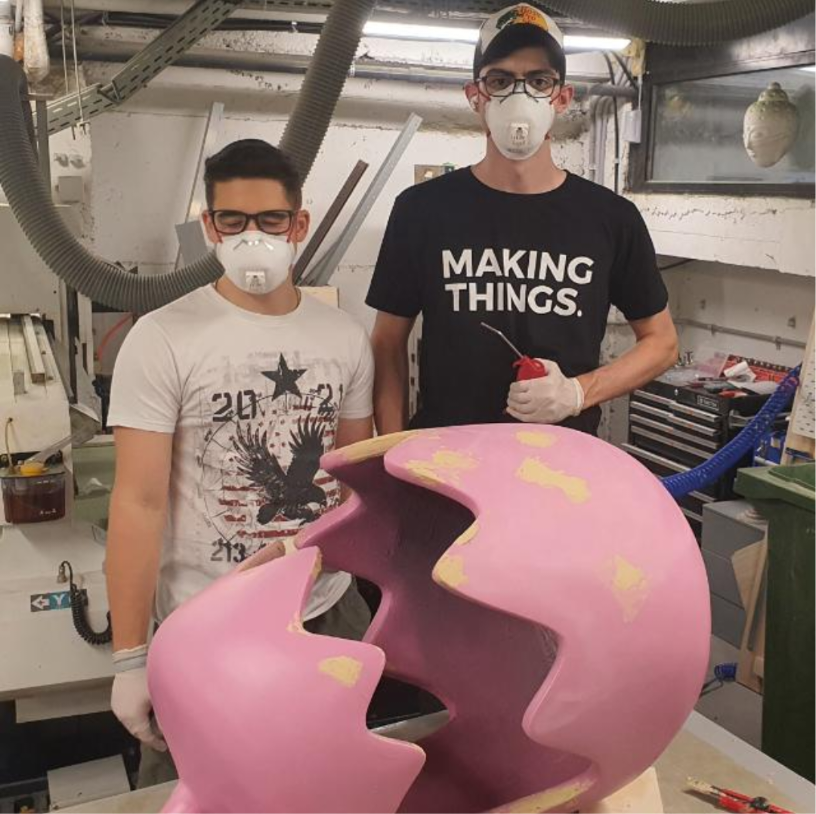

After two design iterations, the third version fully solved the problem. The printer saw much more frequent use afterward, including for large sculptural prints.

ACCESIBILITY MENORAH & ELECTRIC LIGHTER

I designed a custom menorah and an electric lighter intended for a person with limited motor control. The system was designed to be easy to operate and reliable.

Although the project was ultimately unable to be delivered to a planned event in Dubai due to external complications, the device itself worked exactly as intended and remains one of my favorite accessibility-focused projects.

CUSTOM ESPORTS TROPHIES

While living in Israel, I was heavily involved in the local esports community and wanted to give back by creating custom trophies.

I designed the trophies in CAD, printed the main bodies, and personally handled sanding and painting. The bases were made from salvaged wood: I recovered a broken desk from a dumpster near the shop, laminated the wood to create thicker stock, and machined the bases on a CNC router.

Each base contained a recessed cavity with an embedded NFC chip customized to the award recipient, some designs I whipped up in photoshop and transferred to the wood using acetone transfer, and Oil-finished wood and felt-backed bases. They feel very weighty and premium, and the reception was overwhelmingly positive.

OTHER PROJECTS

A large statue we made for a company of their mascot.

Assembling motion-activated soap displays for Sabon, a luxury soap brand.