One of the HP 5200s and the cleaning station

Loading an HP product onto a truck to ship to a customer

My office plaque!

Impac Systems Engineering is an additive manufacturing facility and engineering firm based in Temple, Texas, with a strong focus on production-scale printing, manufacturing services, and the sale of industrial machines, parts, and consumables. I first met the Impac team after visiting their booth at 3DEXPERIENCE World 2025, where I was impressed by the quality and scale of what they were producing. After reaching out, they contacted me a few months later about an opportunity to join the team.

At Impac, I operated and maintained a wide range of industrial additive manufacturing platforms, including MJF, large and small-format FDM, SLA, and LPBF systems. A bunch of my time was spent running three HP Jet Fusion printers (two 5200s and a 4200), manufacturing thousands of parts for paying customers. I handled end-to-end production, including print setup, depowdering, cleaning, sandblasting, dyeing, metal finishing, packaging, and shipping. I was also responsible for routine cleaning and upkeep of the HP systems to keep them running reliably.

Manufacturing was not the only part of my role. I also took on several internal engineering and workflow projects that had lasting impact across the company.

NEW INVENTORY SYSTEM

Before I arrived, inventory tracking at Impac was inefficient and incomplete, which resulted in tens of thousands of dollars of parts and consumables being effectively unaccounted for. I designed and implemented a company-wide smart inventory system from scratch using Airtable. The system tracks parts, consumables, and active orders, and maps where each job sits in the production timeline. After deploying it, I taught it to the rest of the team so it could be used consistently across the company. The system is still in use and saves both time and money on a daily basis.

WORKFLOW OPTIMIZATION

I also made several hands-on improvements to the manufacturing workflow by designing custom tools and organizational solutions:

Sandblaster refill attachment: Refilling abrasive media was slow, messy, and poorly designed. I engineered a custom refill attachment that allows media to be quickly poured directly from the bag into the hopper without spillage. The tool was so well received that it is now included as a free add-on with sandblasters sold by Impac.

Formlabs resin vat storage: Vats were previously stacked in unstable piles that risked damaging the underlying plastic window. I designed modular, protective shelves to safely store and organize them. The vats also fit in with a super satisfying click.

These changes saved multiple hours every week and improved consistency and safety on the shop floor.

Two of the formlabs modular shelves

The dye tag 'pringles'

Me doing a demo for the HP at an open house

CUSTOMER OUTREACH

To help expand company outreach, I modeled, printed, and post-processed sample parts for prospective customers to showcase Impac’s capabilities. My favorite examples were a set of DyeMansion dye tags we nicknamed “Pringles” due to their shape, which became a memorable demonstration piece for customers. These dye tags were produced specifically for a company open house, where I also ran a live demonstration of the HP MJF system. I walked visitors through the printing workflow, explained the advantages of MJF at production scale, and answered technical questions from engineers, business owners, and prospective customers.

SIDE PROJECTS

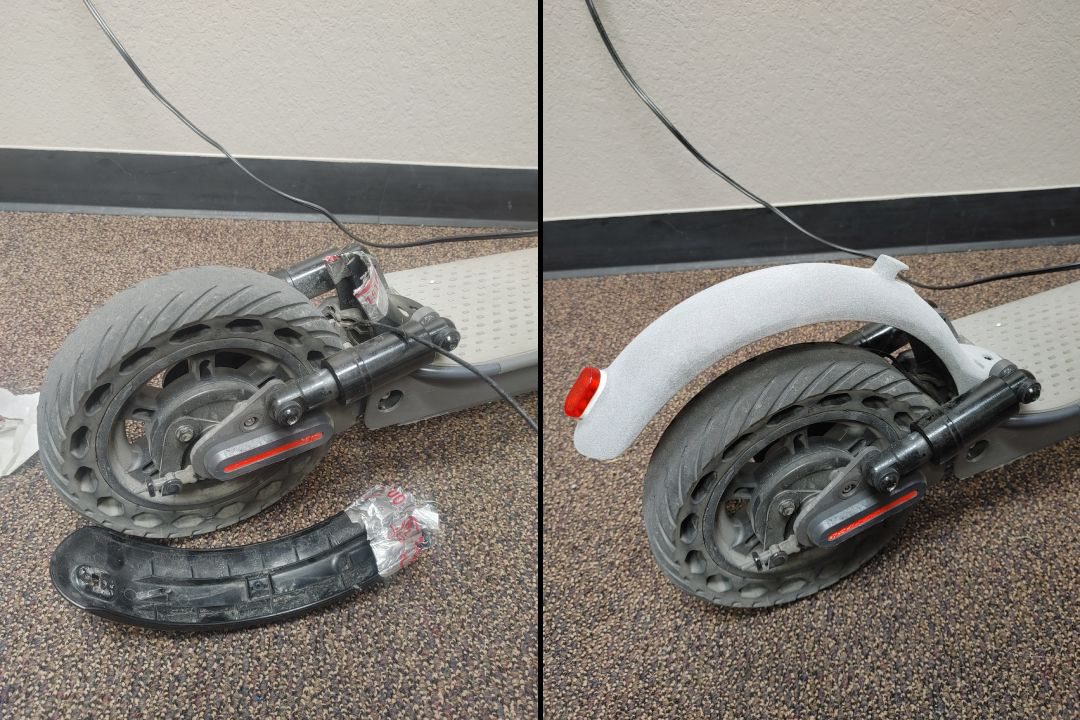

On the more practical side, I also learned how to operate a forklift, and I took on a personal side project that doubled as a real-world test of Impac’s capabilities. My electric scooter’s rear wheel guard had snapped, so I temporarily repaired it, scanned the part using an Artec Spider II, and printed a replacement on the HP MJF. The final part was stronger than the original, and it solved a real problem using the same tools we relied on for customer work.

This role blended high-volume production, process engineering, design, and systems thinking. It pushed me beyond “just printing parts” and into building durable solutions that improved how the entire operation functioned.

Scooter guard before and after fix