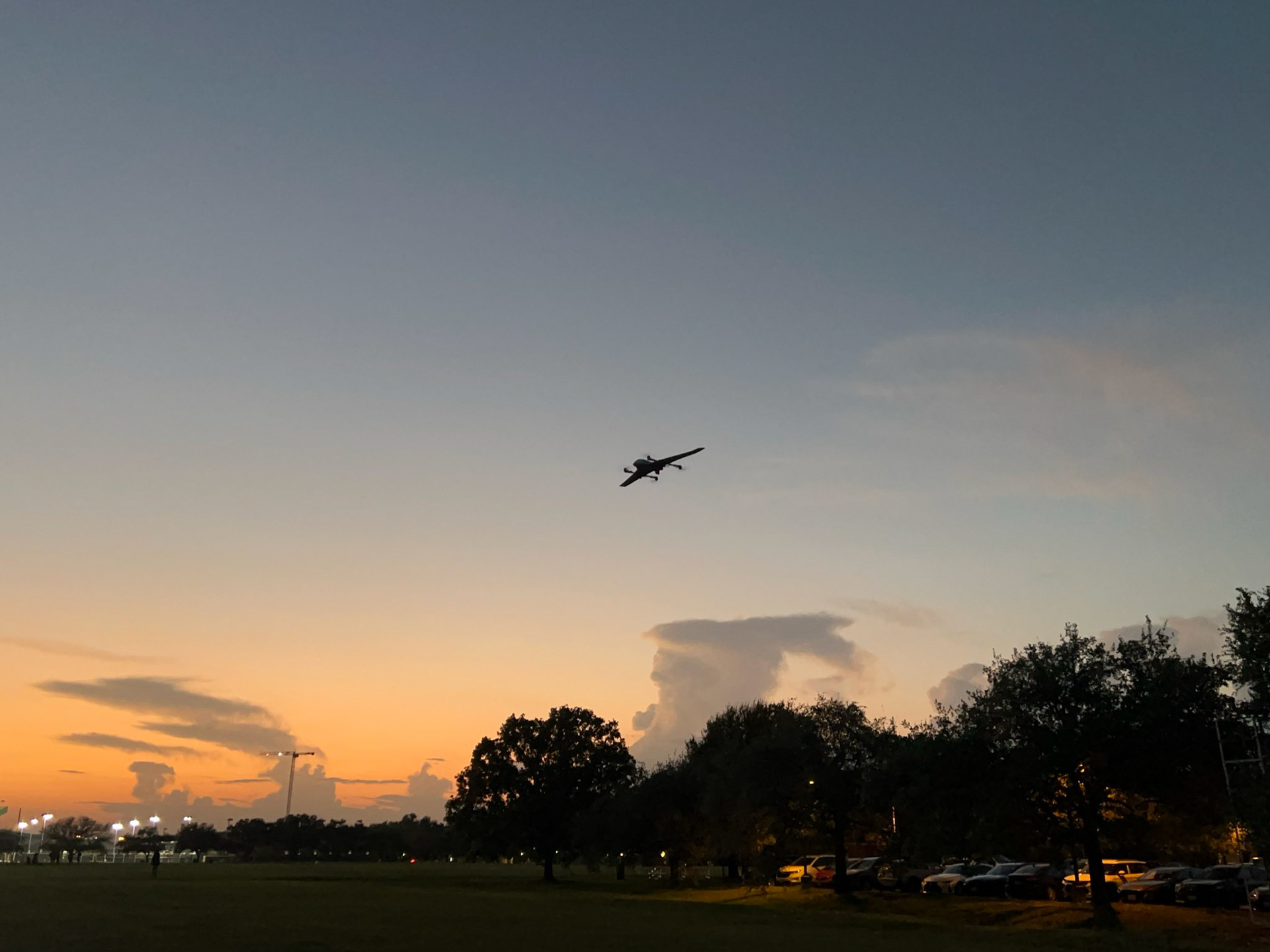

A test-flight of our drone

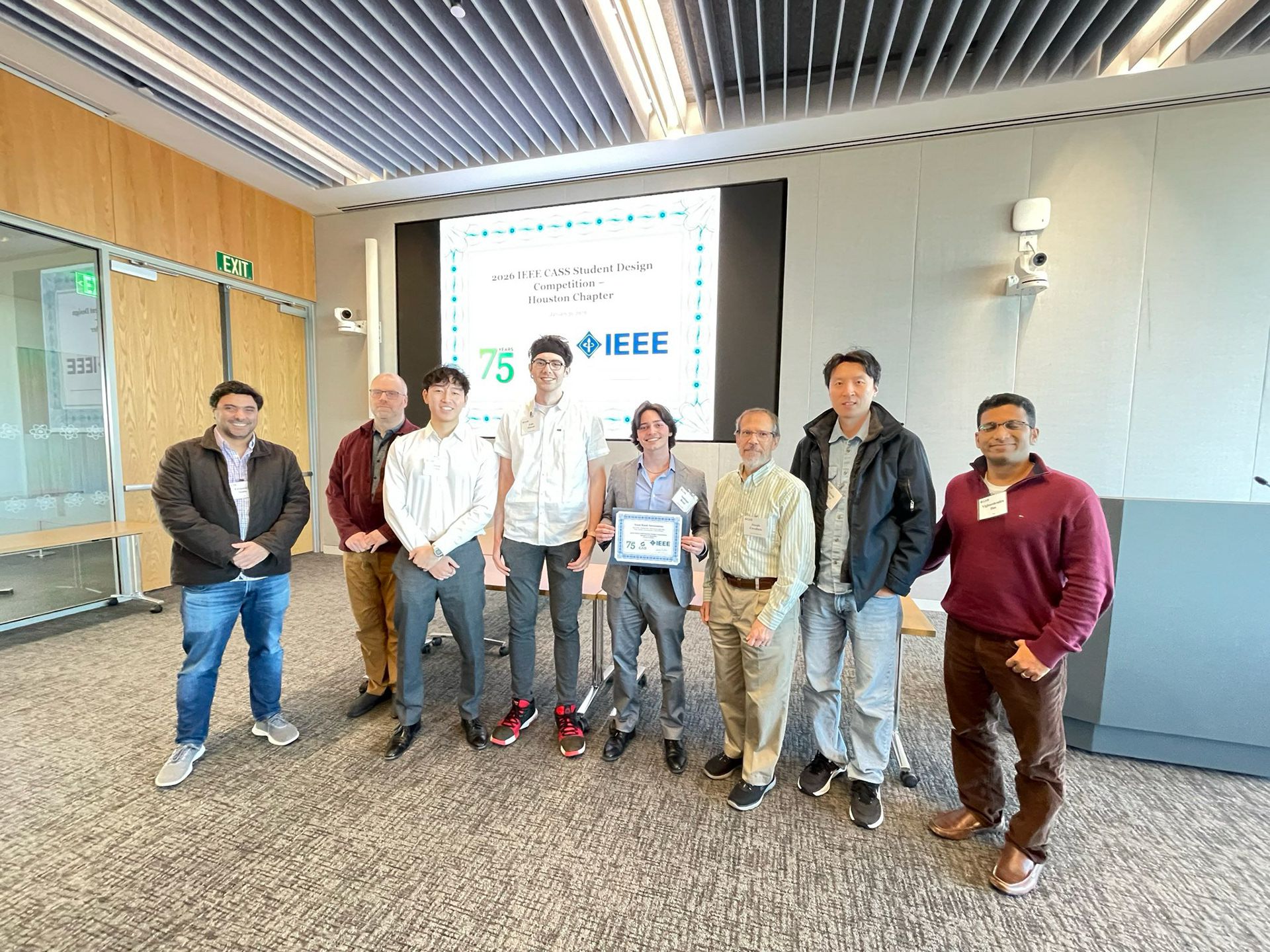

Group photo of the engineering team

As part of my senior capstone project, I am a member of a six-engineer team developing an autonomous VTOL drone designed to transport sensitive medical biologics such as organs, blood, and antivenom. Haast Autonomous is a startup founded by Rice students with the goal of fixing major inefficiencies in the medical transport system. Today, the process relies on private jets, ambulances, and couriers, creating excessive cost, delays, and handoffs. Roughly 40% of donor organs go unused due to these inefficiencies.

Our system aims to reduce cost, complexity, and risk by enabling direct, autonomous transport.

Our system aims to reduce cost, complexity, and risk by enabling direct, autonomous transport.

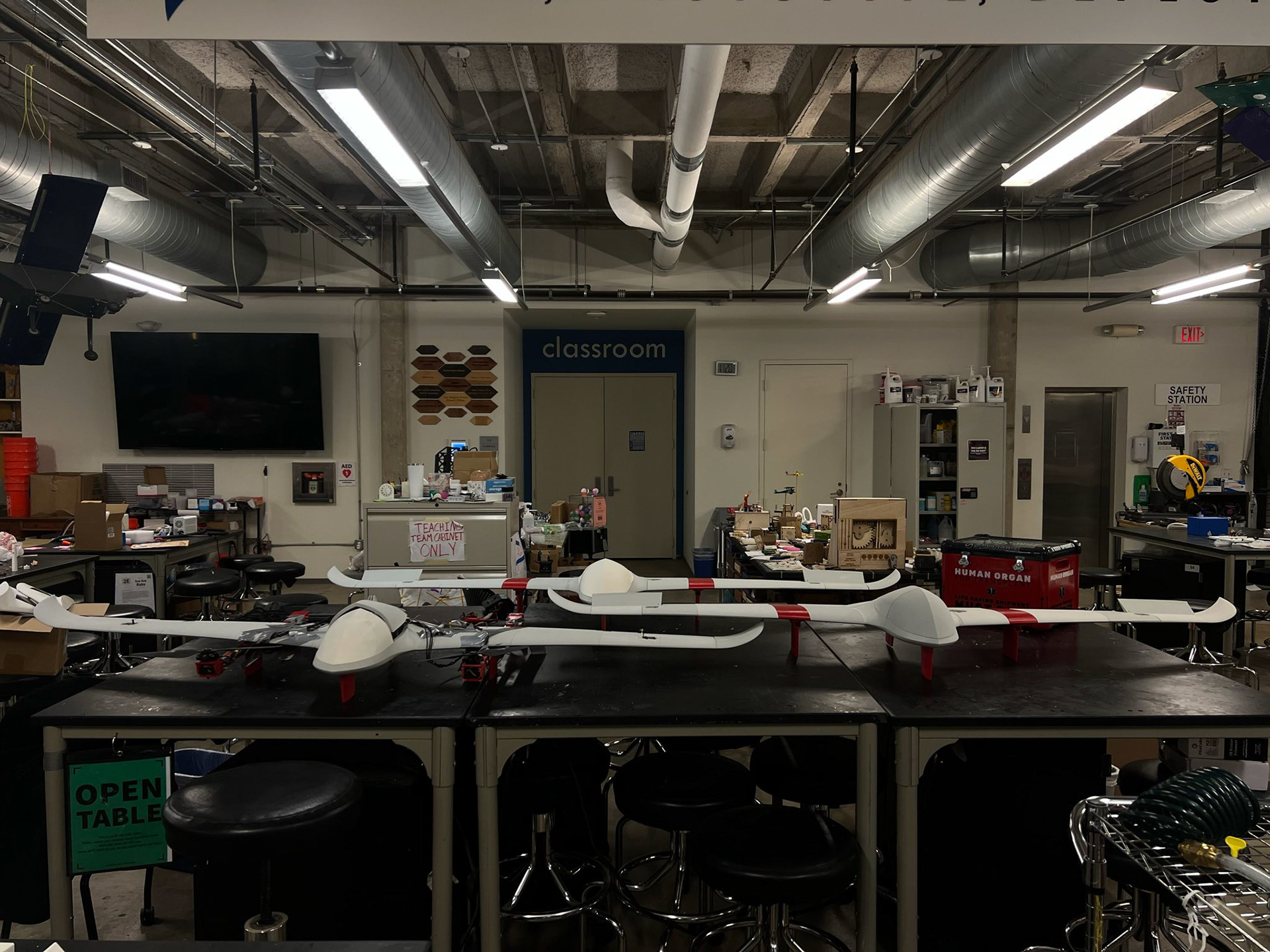

VEHICLE AND ITERATION

The current iteration of the drone is being designed to carry a 4 × 4 × 6 inch payload, weighing up to 3 lbs, over distances exceeding 50 km. Rapid iteration is central to our approach. We use 3D printing to prototype aggressively, often manufacturing and flight-testing a revised airframe every week. This allows us to validate design changes quickly instead of locking into slow, traditional development cycles. Once this smaller variation is complete, we have plans to move onto a larger variation that can transport larger payloads.

MATERIALS

My work on the team focuses on part manufacturing, material selection, and weight optimization.

We print the primary airframe using PLA Aero and ASA Aero due to their active foaming properties, which dramatically reduces weight while maintaining stiffness. Higher-stress components are printed in PPA-CF or ABS for strength and durability.

Printing PPA-CF presented a major challenge. The Rice makerspace did not allow us to print this material on the fancy Bambulabs, so I retrofitted an older Prusa i3 MK3 to handle a filament it was never designed to print. Through tuning, enclosure control, and process experimentation, I developed a reliable workflow for producing high strength-to-weight PPA-CF parts on that machine, outperforming comparable ABS components.

PROCESS INNOVATION

We discovered that printing Aero filaments like standard solid filaments was inefficient. It caused surface defects, wasted material, and unnecessary mass. To fix this, I developed a printing method specifically optimized for Aero materials.

By introducing precise ultra-thin grid-like cuts throughout the part, it tricks the slicer into treating internal features as part of the outer contour when spiral vase-mode is enabled. After printing, a thin coat of sealant adds surface rigidity and durability. This method:

- Reduces part weight, print time, and material usage by roughly 50%

- Virtually eliminates surface defects

- Virtually eliminates surface defects

Simply by changing how the parts were printed rather than redesigning the vehicle, I reduced the total drone mass by about 0.5 kg, which is a significant improvement for a platform of this size.

Parts drying on a rack after being treated with Flex Seal

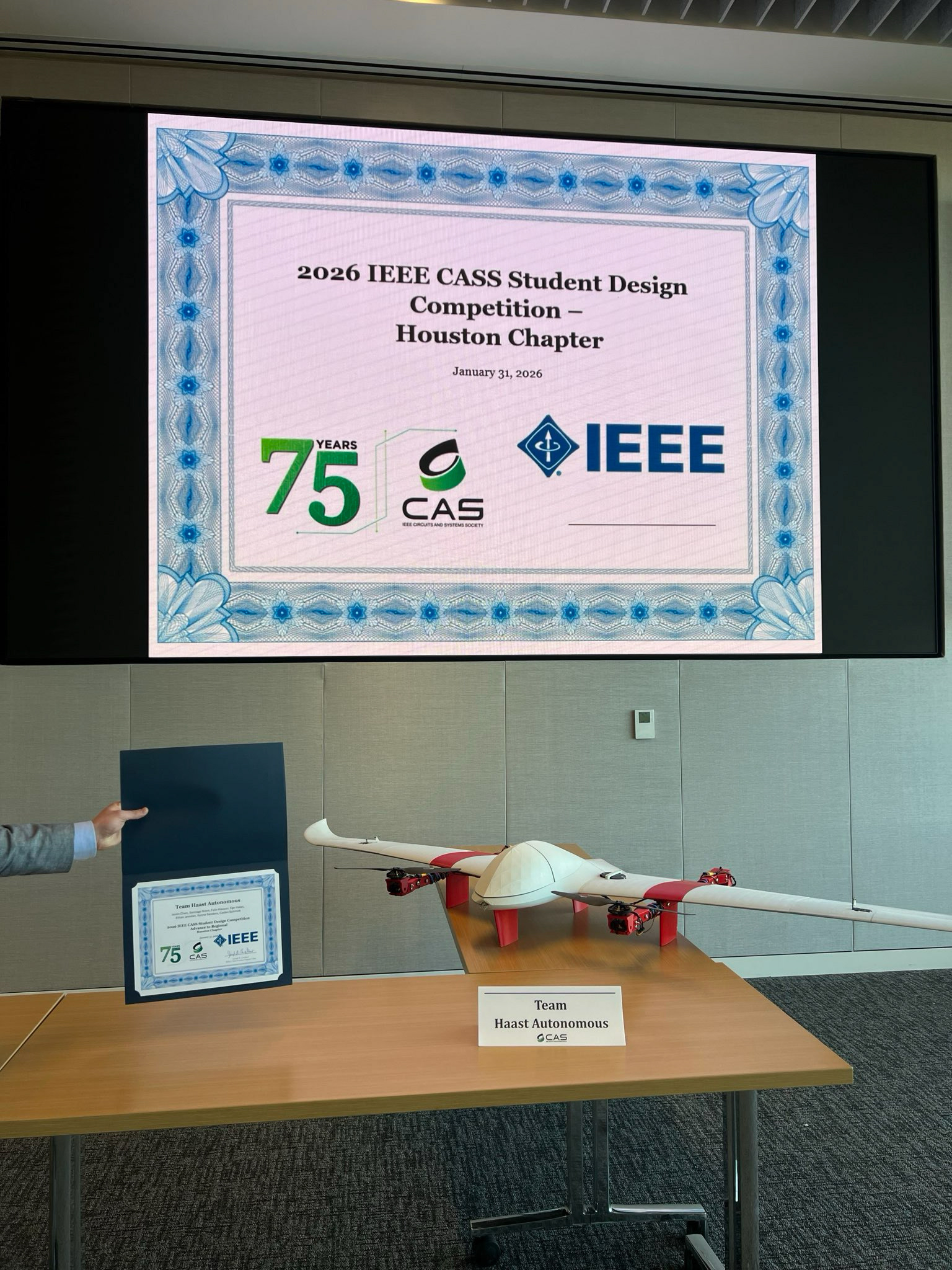

IEEE CASS STUDENT DESIGN COMPETITION

The Haast team is competing in the IEEE Circuits and Systems Society (CASS) Student Design Competition, an international engineering competition where teams present and demo their projects to a panel of judges. We have advanced to the second round and are representing the Houston chapter at the regional level. The competition is ongoing, and advancing past this round would qualify us for the final round in Shanghai.